SikaFlex 522 weather-resistant universal adhesive sealant stell grey 300 ml

4.5 (666) · € 7.00 · En Stock

SikaFlex 522 weather-resistant, low-emission universal adhesive sealant black 300 ml/410g PRODUCT BENEFITSHigh ageing and weathering resistantHigh fungicidal resistanceVery low emission and odorBonds well to a wide variety of substrates without the need for special pre-treatmentHigh color stability under UVIsocyanate, solv

SikaFlex 522 weather-resistant, low-emission universal adhesive sealant black 300 ml/410g PRODUCT BENEFITSHigh ageing and weathering resistantHigh fungicidal resistanceVery low emission and odorBonds well to a wide variety of substrates without the need for special pre-treatmentHigh color stability under UVIsocyanate, solvent, phthalate and silicone-freeMeets hygiene requirements for ventilation and air-conditioning systems and units according VDI 6022 Blatt 1:2011-07ISEGA certificate for foodstuff area usageEC1+ certificate Areas of ApplicationSikaflex®-522 adheres well to a wide variety of substrates and is suitable for interior and exterior elastic sealing and bonding applications. It is suitable for applications in areas of air ventilation and incidental food contact. Suitable substrate materials include timber, glass, metals, metal primers and paint coatings (2-part systems), ceramic materials and plastics. Seek manufacturer’s advice and perform tests on original substrates before using Sikaflex®-522 on materials prone to stress cracking. This product is suitable for experienced professional users only. Tests with actual substrates and conditions have to be performed ensuring adhesion and material compatibility. Product Details Typical Product Data Chemical base Silane Terminated Polymer Color (CQP001-1) White, grey, black Cure mechanism Moisture-curing Density (uncured) 1.4 kg/l Non-sag properties Good Application temperature 5 ─ 40 °C Skin time (CQP019-1) 30 minutes Curing speed (CQP049-1) (see diagram) Shrinkage (CQP014-1) 2 % Shore A hardness (CQP023-1 / ISO 48-4) 40 Tensile strength (CQP036-1 / ISO 527) 1.8 MPa Elongation at break (CQP036-1 / ISO 527) 400 % Tear propagation resistance (CQP045-1 / ISO 34) 7.5 N/mm Service temperature (CQP513-1) 4 hours 1 hour -50 ─ 90 °C 140 °C 150 °C Shelf life Unipack / CartridgeDrum 12 months9 months Application Information Surface preparationSurfaces must be clean, dry and free from grease, oil and dust. Surface treatment depends on the specific nature of the substrates and is crucial for a long lasting bond. Suggestions for surface preparation may be found on the current edition of the appropriate Sika® Pre-Treatment Chart. Consider that these suggestions are based on experience and have in any case to be verified by tests on original substrates. ApplicationSikaflex®-522 can be processed between 5 °C and 40 °C (climate and product) but changes in reactivity and application properties have to be considered. The optimum temperature for substrate and sealant is between 15 °C and 25 °C. Consider that the viscosity will increase at low temperature. For easy application, condition the adhesive at ambient temperature prior to use. Sikaflex®-522 can be processed with manual, pneumatic or electric driven piston guns as well as pump equipment. The skin time is significantly shorter in hot and humid climate. For advice on selecting and setting up a suitable pump system, contact the System Engineering Department of Sika Industry. Tooling and finishingTooling and finishing must be carried out within the skin time of the sealant. It is recommended using Sika® Tooling Agent N. Other finishing agents must be tested for suitability and compatibility prior the use. RemovalUncured Sikaflex®-522 can be removed from tools and equipment with Sika® Remover-208 or another suitable solvent. Once cured, the material can only be removed mechanically.Hands and exposed skin have to be washed immediately using hand wipes such as Sika® Cleaner-350H cleaning towels or a suitable industrial hand cleaner and water. Do not use solvents on skin. OverpaintingSikaflex®-522 can be best painted within the skin formation time. If painting process takes place after the sealant has built a skin, adhesion could be improved by treating the joint surface with Sika® Aktivator-100 or Sika® Aktivator-205 prior to paint process. If the paint requires a baking process (> 80 °C), best performance is achieved by allowing the sealant to fully cure first. All paints have to be tested by carrying preliminary trials under manufacturing conditions. The elasticity of paints is usually lower than that of sealants. This could lead to cracking of the paint in the joint area. Warningtrimethoxyvinylsilane 2-octyl-2H-isothiazole-3-oneH317 May cause an allergic skin reaction.H412 Harmful to aquatic life with long lasting effects.P101 If medical advice is needed, have product container or label at hand.P102 Keep out of reach of children.P261 Avoid breathing mist or vapours.P273 Avoid release to the environment.P280 Wear protective gloves.P501 Dispose of contents/container in accordance with local regulation.EUH211 Warning! Hazardous respirable droplets may be formed when sprayed. Do not breathe spray or mist.

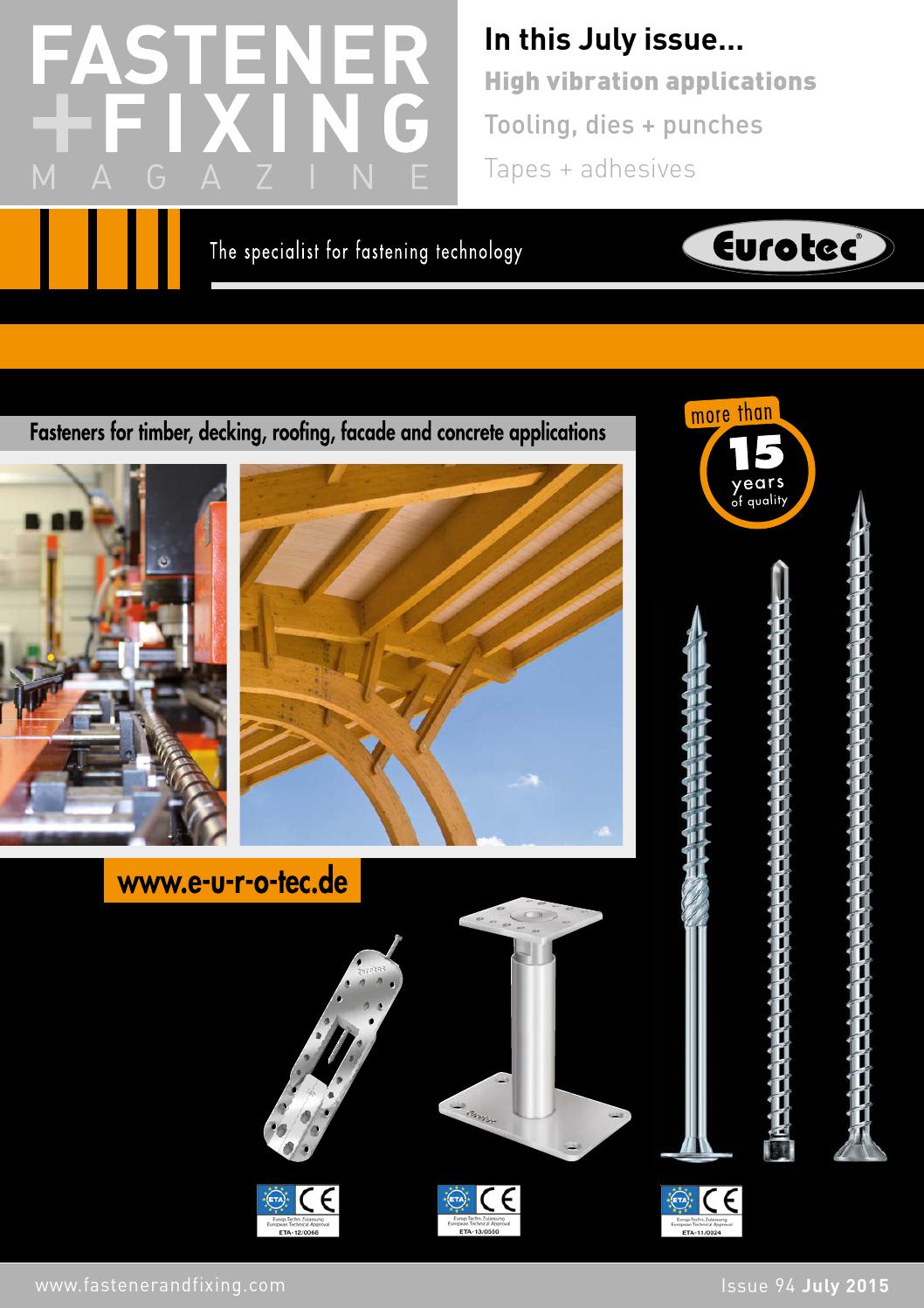

Fastener + Fixing Magazine #94 by Fastener + Fixing Magazine - Issuu

Sikaflex 221 vs Sikaflex 522 - Grove Shop

Compare prices for Silka across all European stores

Sika Sikaflex 295 UV Black 10.3 Oz 300 Ml Cartridge 412132 Boat

Sikaflex 522 Caravan & Motorhome Sealant - Sealant Supplies Ltd

Sika Sikaflex-522 Caravan And Motorhome Adhesive Sealant

Sika Flex 522 Caravan Steel Grey 300 ml STP Universal Adhesive

1 x Sika 522 Caravan Sealant Adhesive WHITE Bonding Motorhome 10

Sikaflex-522 weather-resistant, UV-stable, adhesive sealant (new

Sikaflex®-522 Exterior Assembley Sealing & Bonding

Sikaflex 522 Caravan & Motorhome Sealant - Sealant Supplies Ltd

Compare prices for dichtstofftechnik24 across all European

1 x Sika 522 Caravan Sealant Adhesive WHITE Bonding Motorhome 10